Usually, it takes me more than 30 hours to make one pipe. I start my work with... an idea. Then I put a paper and a pencil to use: there is no way to set to work without an engineering drawing of a pipe, at least a sketch. When the drawing is ready, it's time to choose the right piece of briar.

I use the lathe to drill tobacco hole and air hole only. The main part of work I do by hand.

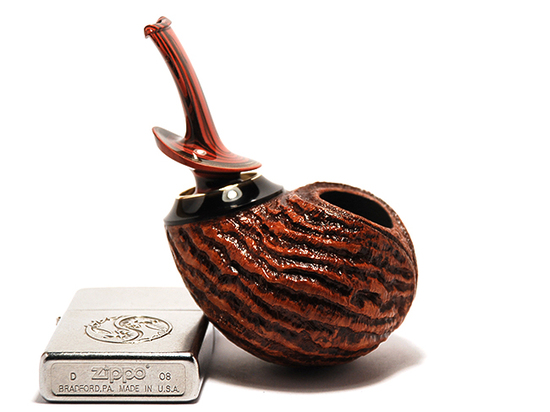

As for me, an engineering of a pipe is greatly important as well as its design. That's why no defect or carelessness in work can be tolerated. I pay much attention to polishing an air hole in the mouthpiece, although many think there is no necessity at all. But I think that the air hole polished to shine has a beneficial effect on the smoking process as well as easy cleaning of a pipe.

I make all my pipes of Mediterranean briar, as a rule, Italian one by Romeo Domenico (Mimmo) and Manno Briar.

The mouthpieces in my pipes are all hand cut of German Ebonite, as a rule, the SEM's one.

As an application, I use the exotic wood, horn, bone and imitation elephant ivory.